Ask Matt / FAQ

What does the term SEER RATING refer to?

How often should I change the air filter in my system?

TIP: Write the install date on the filter, so you will always know how long it has been “in service”

What is the difference between an R-22 and a R-410A Puron system?

Puron Refrigerant: Puron® Refrigerant is an environmentally sound refrigerant designed not to harm the earth’s ozone layer. Federal law requires all manufacturers phase out ozone depleting refrigerants in the next few years.

How to get an Energy Tax Credit/Rebate

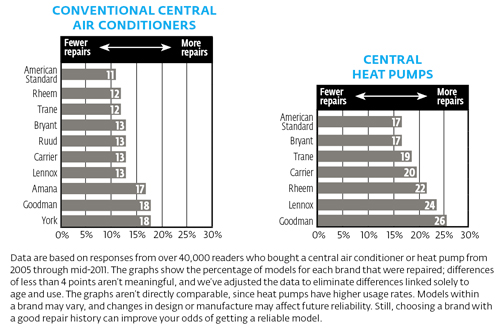

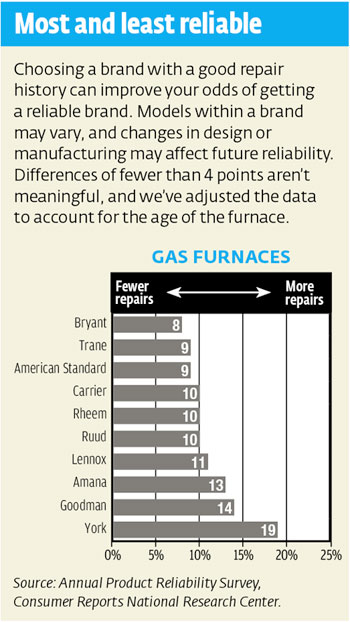

Reliability Chart for Gas Furnaces, Air Conditioners and Heatpumps and from Consumerreports.org

Big energy savings over earlier central air conditioners is one more reason to install a new one or replace an old one that broke. But you may want to give Amana, Goodman, and York the cold shoulder. All three brands logged the most repairs in our latest reliability surveys of more than 40,000 readers who bought a central-air-conditioning system (see charts below).

Goodman, along with Rheem and Lennox, was also among the more repair-prone brands of central heat pumps, which exchange hot air for cool air in summer and do the opposite in winter. The added complexity of these systems and the fact that they’re used for more of the year may help explain why 20 percent of them needed repair compared with just 13 percent for central air conditioners.

The surveys, from the Consumer Reports National Research Center, also show that fixing any central A/C system can be a real headache. Some 39 percent of subscribers who repaired either type were left without cooling for at least a day. Ten percent reported repeated repairs during the first year after installation, and 18 percent said their system broke down completely. What’s more, the roughly 30 percent who had problems shelled out $150 or more for the repair.

The good news: Choosing one of the more reliable brands in our survey can boost the odds that you will be comfortable. Here are some other steps that will help you minimize repairs and trim your cooling bill:

Hire your own installer. Our research showed a strong correlation between repairs and installation. For central A/Cs, 19 percent of systems installed by new-home builders failed compared with 12 percent installed by homeowners. The gap was even wider for heat-pump units, where 28 percent of the builder-installed units failed compared with 18 percent for owner-installed systems.

Keep it clean. Be sure hedges and plants are at least 2 feet away from the outside unit. Clean grills and filters monthly. Clear debris and dirt from condenser coils and check for blockages in the drain pipe.

Seal and insulate ducts. Up to 30 to 40 percent of energy can escape through leaks or when ducts aren’t insulated.

For more information on cooling your home, check out our buying guides for window air conditioners and central air conditioners.

We proudly offer BRYANT and AMERICAN STANDARD Equipment. Please CONTACT US for a quote

Ductless Mini Split A/C units

Ductless, mini split-system air-conditioners (mini splits) have numerous potential applications in residential, commercial, and institutional buildings. The most common applications are in multifamily housing or as retrofit add-ons to houses with “non-ducted” heating systems, such as hydronic (hot water heat), radiant panels, and space heaters (wood, kerosene, propane). They can also be a good choice for room additions and small apartments, where extending or installing distribution ductwork (for a central air-conditioner or heating systems) is not feasible.

Like central systems, mini splits have two main components: an outdoor compressor/condenser, and an indoor air-handling unit. A conduit, which houses the power cable, refrigerant tubing, suction tubing, and a condensate drain, links the outdoor and indoor units.

ADVANTAGES

The main advantages of mini splits are their small size and flexibility for zoning or heating and cooling individual rooms. Many models can have as many as four indoor air handling units (for four zones or rooms) connected to one outdoor unit. The number depends on how much heating or cooling is required for the building or each zone (which in turn is affected by how well the building is insulated). Each of the zones will have its own thermostat, so you only need to condition that space when it is occupied, saving energy and money.

Ductless mini split systems are also often easier to install than other types of space conditioning systems. For example, the hook-up between the outdoor and indoor units generally requires only a three-inch (~8 centimeter [cm]) hole through a wall for the conduit. Also, most manufacturers of this type of system can provide a variety of lengths of connecting conduits. So, if necessary, you can locate the outdoor unit as far away as 50 feet (~15 meters [m]) from the indoor evaporator. This makes it possible to cool rooms on the front side of a building house with the compressor in a more advantageous or inconspicuous place on the outside of the building.

Since mini splits have no ducts, they avoid the energy losses associated with ductwork of central forced air systems. Duct losses can account for more than 30% of energy consumption for space conditioning, especially if the ducts are in an unconditioned space such as an attic.

Compared with other add-on systems, mini splits offer more flexibility in interior design options. The indoor air handlers can be suspended from a ceiling, mounted flush into a drop ceiling, or hung on a wall. Floor-standing models are also available. Most indoor units have profiles of about seven inches (~18 cm) deep and usually come with sleek, high-tech-looking jackets. Many also offer a remote control to make it easier to turn the system on and off when it’s positioned high on a wall or suspended from a ceiling. Split-systems can also help to keep your home safer, because there is only a small hole in the wall. Through-the-wall and window mounted room air-conditioners can provide an easy entrance for intruders.

DISADVANTAGES

The primary disadvantage of mini splits is their cost. Such systems cost about $1,500 to $2,000 per ton (12,000 Btu per hour) of cooling capacity. This is about 30% more than central systems (not including ductwork) and may cost twice as much as window units of similar capacity.

The installer must also correctly size each indoor unit and judge the best location for its installation. Oversized or incorrectly located air-handlers often result in short-cycling, which wastes energy and does not provide proper temperature or humidity control. Too large a system is also more expensive to buy and operate.

Some people may not like the appearance of the indoor part of the system. While less obtrusive than a window room air conditioner, they seldom have the built-in look of a central system. There must also be a place to drain condensate water near the outdoor unit.

Qualified installers and service people for mini splits may not be easy to find. In addition, most conventional heating and cooling contractors have large investments in tools and training for sheet metal duct systems. They need to use (and charge for) these to earn a return on their investment, so they may not recommend ductless systems except where a ducted system would be difficult for them to install.